System descriptions

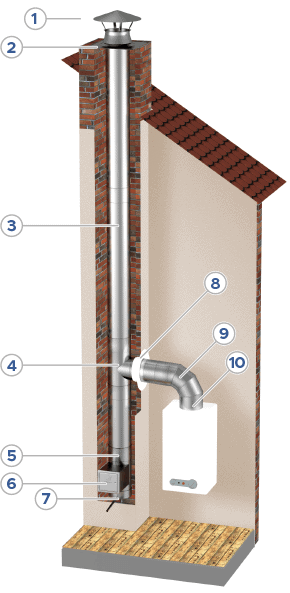

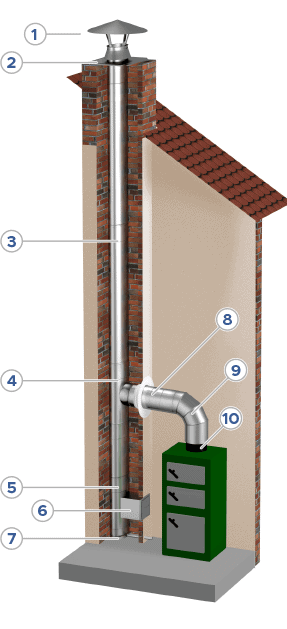

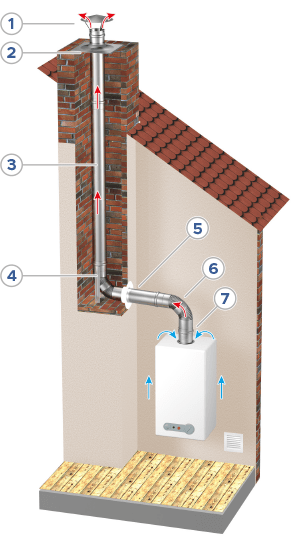

Negative pressure chimney systems

KF chimney liners

Chimney liners are an extremely important and, at the same time, the main part of a chimney. Due to their continuous and direct contact with smoke, it is important to construct them correctly and to use proper materials. Thanks to complete tightness, they ensure the safety of using an exhaust system. They can be used in residential and industrial construction, and their assembly consists in properly placing the chimney liner inside an already existing chimney as a protective insert. It is one of the many solutions allowing to modernize an old chimney – not only will it additionally secure the discharge of smoke, but also significantly reduce heating costs and ensure the functionality of the entire heating system, including the boiler.

Komin-Flex chimney liners are manufactured with the use of acid-resistant steel. Thanks to its properties, it protects the liner and the entire chimney against the aggressive effects of acidic condensate generated during the combustion process. Low thermal inertia of the used materials, resulting in the possibility of quickly heating the chimney during a boiler's cyclic operation, increases the chimney draft and the installation's efficiency.

- Chimney cap

- Roof passage

- Straight pipe

- Tee 87°

- Cleaning hatch

- Cleaning hatch doors

- Cleaning hatch bottom

- Rosette

- Elbow 87º

- Coupling

thickness 0,5; 0,8; 1,0 mm

thickness 0,8; 1,0 mm

OWAL chimney liners

Oval chimney liners are intended mainly for renovating brick chimneys or for changing the purpose of the previously built ceramic rectangular ducts due to the use of more modern heating devices. They are used to take full advantage of the cross-section of the existing ceramic chimney, usually with a smoke channel cross-section of 14x27 cm, when installing typical round-section liners would excessively narrow the smoke duct, reducing the chimney's efficiency.

Due to the specific character of solid fuel combustion, meaning periodically occurring high temperatures, soot accumulation and the possibility of its ignition, elements of the chimney liner should be made of metal sheets guaranteeing significant thermal resistance. For this purpose, acid-resistant steel with a thickness of 0.8 mm is used. When using a steel liner, wet and aggressive combustion compounds do not come into contact with the ceramic chimney, thus ensuring longer life of the chimney.

Similarly to KF type chimney liner systems, oval elements are connected with extended ends (muff – 100 mm), which makes the system simple to install, guarantees tightness and compensates linear elongations resulting from the work temperature.

Oval chimney liners can be made entirely of oval-section elements or partially of oval-shaped elements connected through a shape reduction fixture with other elements of a typical round section. Oval chimney liners have are CE-marked and compliant with the European and Polish quality standards.

- Cap

- Roof passage + OPD

- Straight pipe oval

- Tee 87° oval

- Cleaning hatch oval

- Doors

- Bottom oval

- Rosette

- Elbow

- Reduction piece

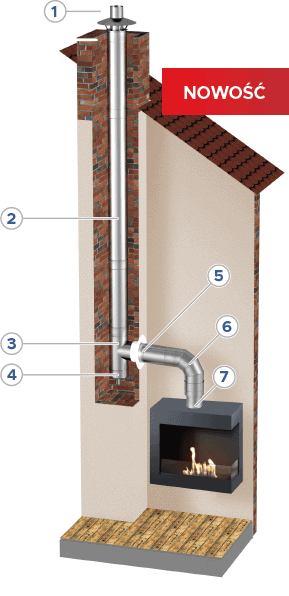

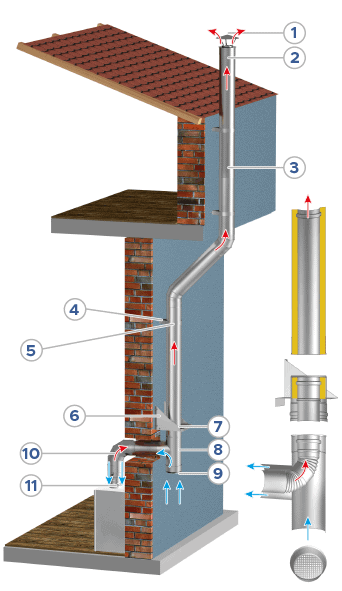

GAZKOM chimney liners

New generation of fireplaces – gas fireplaces – requires the use of special chimney systems. Designed with comfort and safe operation in mind, the devices require reliable smoke discharge. The GAZKOM steel concentric smoke/air system is a way to address these needs. Smoke is discharged through the internal duct, while the external duct supplies the fireplace with air, necessary for combustion. The system allows for operation regardless of the ventilation in the room in which a fireplace is installed. The GAZKOM system, resistant to high smoke temperature amplitudes occurring during the operation of gas fireplaces (thermal resistance T450°C, periodically up to 600°C), with a structure ensuring compensation of thermal elongations, is characterized by low flow resistance, which is particularly important in balanced flue self-suction systems. GAZKOM elements allow connecting a gas fireplace in several configurations. The basic method of installation is using the existing brick chimney, where the GAZKOM liner is placed. Another way is a side outlet and air intake from behind the building’s wall. Smoke can also be discharged above the building's roof. In this case, the SPS IZOL system is used. The system is installed outside the building with a special air intake located in the lower part of the chimney connected to GAZKOM.

The system is characterised by permanently welded centring elements in the fittings, ensuring concentricity and a protruding flue of the internal element, working in favour of easy assembly (no clamps) with a guarantee of a stable and rigid structure. Elements connected with the use of socket ends (60 mm – muff) enable the liner's free dilatation. The system works under negative pressure (it is not equipped with gaskets).

GAZKOM chimney liners are CE-marked and compliant with the European and Polish quality standards.

- Ventilated chimney cap

- Air-flue pipe

- Tee GAZKOM

- Intake bottom

- Rosette

- Elbow GAZKOM

- Adapter

Examples of connection variants

Download the manual View all the items

thickness 0,5 mm

internal elements thickness 0,8 mm

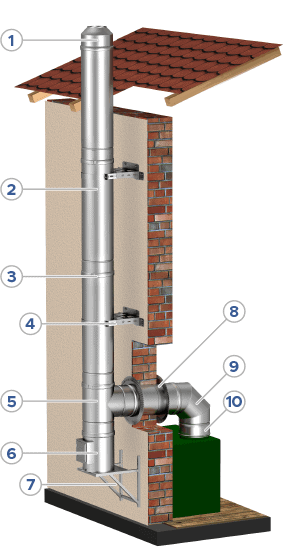

KF insulated chimneys

Insulated chimneys are systems used in both residential and broadly understood industrial construction.

The products are made of acid-resistant steel. They have mineral wool insulation, which allows for flexibility in terms of the location where the insulated KF type chimney is installed – it does not need special protection. It can be located both against a wall and as an independent structure in a supporting construction. Negative pressure chimneys work thanks to the pressure difference that forms between the smoke inlet and the chimney outlet – meaning its upper part. Thanks to this, the lift force, also called chimney draught, is formed in the chimney, which absorbs smoke and discharges it outside.

Insulated chimneys are resistant not only to the harmful effects of substances resulting from combustion, but also to the impact of weather conditions. Thanks to the use of proper materials and welding methods (plasma welding), they guarantee perfect tightness of the elements, durability, and long service life. Insulated KF type chimneys are characterised by high stiffness, achieved thanks to a socket connection (muff – 100 mm), and high thermal resistance enabling the installation of chimneys in the most severe weather conditions. Properly inverted connection sockets (muffs) of the inner pipe and the jacket protect the insulation against getting wet, both inside and outside. The special design of elements and the used insulating materials eliminate the phenomenon of thermal bridges.

KF insulated chimneys are CE-marked and compliant with the European and Polish quality standards.

- Mouthpiece

- Straight pipe

- Mounting clamp

- OBL clip + support

- Tee 87°

- Cleaning hatch

- Support console

- Rosette

- Elbow

- Reduction piece

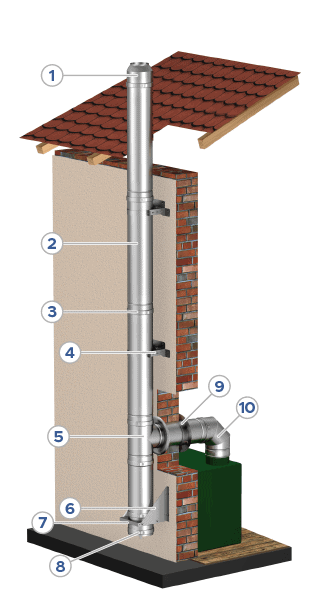

SLIM insulated chimneys

Taking advantage of the many years of experience as well as the changes on the heating installation market, a system of insulated chimneys has been developed with a reduced thickness of fixed insulation, uniform grades of internal and external material (1.4301/304), and thickness (0.5 mm) of the used materials. It is a proposition that meets the current market demand: a safe and durable chimney at an attractive price. The system is reliable everywhere where the dew point is brought outside its range (meaning that the chimney works in dry mode) by taking advantage of the low thermal inertia of the chimney made of thin-walled stainless steel elements. A complete range of boilers and devices, apart from condensing ones, can be successfully used with this type of chimney when the processes and parameters are properly regulated. SLIM is also perfect for ventilation purposes, while its configuration does not cause any problems, thanks to the simple elements of the chimney duct. As a result, the product is durable and solid after assembly.

“Thinning” the system, including limiting the variety of elements and dimensions, is aimed at simplifying, as much as possible, selection, ordering, and assembly. In return, it offers a lower price, without reducing the solution's reliability, quality of workmanship and the used materials. Slim constitutes a classic example of the used technique – it is effective for all types of fuel when maintaining the smoke temperature above 120°C and properly selecting the diameter and height.

The products are made of acid-resistant steel and have mineral wool insulation, which makes it possible to locate a SLIM insulated chimney anywhere, both inside and outside buildings.

Ease of installation with simple and modified chimney duct elements, as well as a construction made of connecting and supporting elements, result in a durable and solid product with high stiffness, achieved thanks to the use of 60 mm long socket connections. The special design of elements as well as the used insulating materials eliminates the occurrence of thermal bridges.

Insulated SLIM chimneys are CE-marked and compliant with the European and Polish quality standards.

- Mouthpiece SLIM

- Pipe SLIM

- Mounting clamp SLIM

- OBL clip + support

- Tee 87° SLIM

- Console support SLIM

- Relieving console plate SLIM

- Bottom SLIM

- Rosette SLIM

- Elbow SLIM

internal elements thickness 0,5 mm

internal elements thickness 0,8 mm

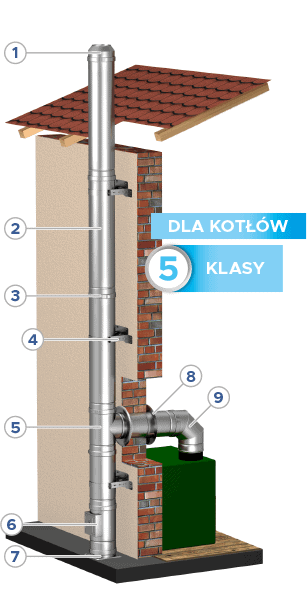

SLIM EKO insulated chimneys

Double-walled SLIM EKO chimneys are designed for difficult working conditions imposed by class 5 boilers compliant with the EcoDesign directive.

Frequent use of poor-quality fuels in traditional boilers is also a threat in the case of modern class 5 boilers, which constitute a response to the energy and ecological needs of the current times. That is why a properly operating chimney, resistant to harmful combustion products, properly thermally insulated, and equipped with all the necessary attributes, is an essential element of proper and long-term operation of a solid fuel-fired boiler of good quality. The SLIM EKO chimney is characterized by these features. It can be used as an external chimney but also recommended, due to the ease of installation and the used materials, as a new internal chimney.

Our experience, supported by scientific studies (e.g. AGH University of Science and Technology), contributed to developing a product made of the best materials and with a construction for the expected difficult working conditions that in a way “enforce” adapting to the basic technical requirements for modern chimney installations. Slim EKO combines the features of negative pressure insulated KF type chimneys (internal material) as well as advantages of the Slim system (insulation thickness, external material, ease of installation, variety of applications).

The essence of the effectiveness of the SLIM EKO insulated metal lies in fully complete elements made of the best grades of chrome steels (stainless, acid-resistant) with the thicknesses adequate to difficult working conditions. Installing elements with a maximum length of 1 m is not problematic and the developed assembly, cleaning, and support elements allow for easy configuration of the chimney. Additional elements of endings, roof passages and covers, consistent with the line, make this system more attractive.

Insulated SLIM chimneys are CE-marked and compliant with the European and Polish quality standards.

- Mouthpiece SLIM EKO

- Pipe SLIM EKO

- Mounting clamp SLIM

- OBL clip + support

- Tee 87º SLIM EKO

- Cleaning hatch SLIM EKO

- Anchor plate SLIM EKO with a bottom

- Rosette SLIM

- Elbow SLIM EKO

Positive pressure chimney systems

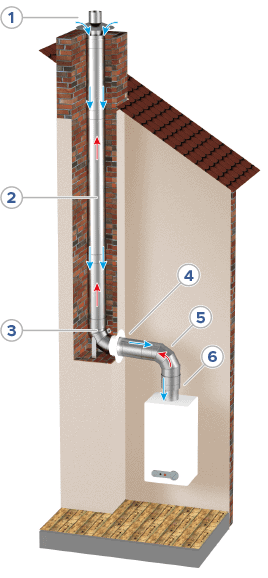

WSPS chimneys

WSPS coaxial smoke/air systems consist of two pipes. Smoke is discharged through the internal pipe, while the space between the external jacket and the smoke pipe is used to supply combustion air.

The tightness of the smoke elements is ensured thanks to specially shaped gaskets. The seal is made of a material that is resistant to combustion products. Thanks to the applied solutions, the elements have the P1 air-tightness class, meaning that they can operate at a positive pressure of up to 200 Pa.

Positive pressure chimney elements are manufactured with the use of acid-resistant steel. Thanks to its properties, it protects the liner and the entire chimney against the aggressive effect of acidic condensate generated during the combustion process. The precisely constructed elements and the socket connection system (muff – 60mm) guarantee the simple assembly and high rigidity of the structure.

Depending on the needs, the WSPS and SPS systems can be combined in any configuration, in accordance with the requirements of the heating device, while maintaining the proper angle of the horizontal sections of smoke pipes.

WSPS chimney systems are CE-marked and compliant with the European and Polish quality standards.

- Ventilated chimney cap

- Straight pipe

- Elbow with support

- Rosette

- Elbow

- Adapter

Examples of connection variants

Download the manual View all the items

thickness 0,4; 0,5 mm

thickness 0,4; 0,5 mm

SPS chimney liners

Separate SPS smoke/air systems consist of two separate pipes, i.e. for discharging smoke and supplying air for combustion.

The tightness of the smoke elements is ensured thanks to specially shaped gaskets. The seal is made of a material that is resistant to combustion products. Thanks to the applied solutions, the elements have the P1 air-tightness class, meaning that they can operate at a positive pressure of up to 200 Pa.

Positive pressure chimney elements are manufactured with the use of acid-resistant steel. Thanks to its properties, it protects the liner as well as the entire chimney against the aggressive effect of acidic condensate generated during the combustion process. The precisely constructed elements and the socket connection system (muff – 60mm) guarantee simple assembly and high rigidity of the structure.

Depending on the needs, the WSPS and SPS systems can be combined in any configuration, in accordance with the requirements of the heating device, while maintaining the proper angle of the horizontal sections of smoke pipes.

SPS chimney systems are CE-marked and compliant with the European and Polish quality standards.

- Cap

- Roof passage

- Straight pipe

- Elbow with support

- Rosette

- Elbow

- Adapter

Examples of connection variants

Download the manual View all the itemsSPS IZOL chimneys

Insulated SPS IZOL systems are made based on SPS positive pressure chimney liners, with additional insulation made of mineral wool with a density of 100 kg/m³ and an outer jacket made of acid-resistant steel. The wool prevents excessive cooling of the chimney walls. In order to ensure stiffness at larger diameters, additional grooves on elements are used. The tightness of the smoke elements is ensured thanks to specially shaped gaskets. The seal is made of a material that is resistant to combustion products. Thanks to the applied solutions, the elements have the P1 air-tightness class, i.e. they can operate at a positive pressure of up to 200 Pa.

The system is designed to be installed outside the building or inside when it passes through an unheated room. Unlike discharging smoke outside the wall, the system of discharging smoke above the roof prevents damaging the facade or smoke penetrating into interiors. The air is supplied directly from the space behind the wall.

Insulated SPS IZOL chimneys are CE-marked and compliant with the European and Polish quality standards.

- Cap

- Upper insulation ending

- Pipe SPS izol.

- OBL W1 support

- OBL clip

- Stress-relieving console support SPS izol.

- Stress-relieving console plate SPS izol.

- Tee elbow 87˚ SPS izol.

- Intake bottom

- Elbow 87˚ WSPS

- Adapter

thickness 0,4; 0,5 mm

Remaining offer

Chimney endings

The used air or smoke are discharged from buildings by gravity, thanks to taking advantage of the natural upward movement of warm air, known as the chimney draft. Hot smoke expands, thus becoming lighter than air, and rises creating an area of lower pressure (negative pressure) in the lower part of the chimney.

Natural chimney draft depends on several factors:

• temperature difference between the smoke and the air outside the building at atmospheric pressure,

• wind, which can generate additional negative pressure in the chimney,

• chimney construction (porosity, narrowing, folds, thermal insulation) and its location in relation to the ridge,

• chimney height and its cross-sectional area,

• topography.

Draft disturbances occur most often as a result of mistakes made during the process of designing and constructing the chimney – if it's too short, it has an insufficient cross-section. The building's location and weather conditions are also important, when there are air turbulences at the chimney outlet. By installing insulated extensions of the ceramic or smoke chimney, we extend the existing chimney and eliminate the phenomenon of excessive cooling of the chimney. By placing a proper cover above it, we eliminate the problem of draft disturbances.

All chimney covers, regardless of whether they are used for ventilation or smoke pipes, should have proper certificates and declarations of conformity issued by the manufacturer, which guarantee proper operation and safety. It is also important to remember that cable outlets should be accessible for cleaning and periodic inspections.

Additional offer

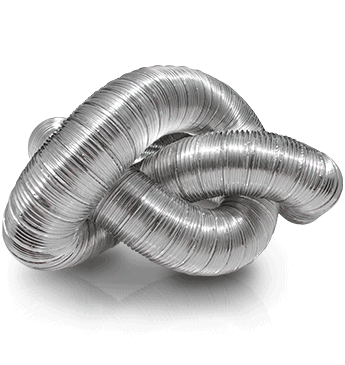

FLEX ventilation ducts made of aluminium tapes with a thickness of 0.08-0.10 mm. In the range of diameters from 80 mm to 200 mm, standard lengths, are compressed for transport to the length of 1 m.

Thanks to the use of precise machines and instruments, a properly shaped tape is coiled and clamped twice, creating tight and durable circular cross-section ducts. The pipe's flexible shape allows it to be compressed and stretched, making it possible to arrange the pipeline in any desired way, without the need for bends and elbows. High flexibility, small bending radius (for example R=160 mm for a diameter of 200 mm), thermal resistance and low weight (for example for a diameter of 200 mm - 0.40 kg) are high utility values of FLEX ducts.

STALFLEX flexible ducts are made of acid-resistant steel tape, similarly to FLEX, spirally coiled and connected with a seam lock. Due to the material used for their production, it is not possible to compress them into shorter sections.

Are you looking for expert advice?

Our consultants are happy to help in selecting chimney system elements.